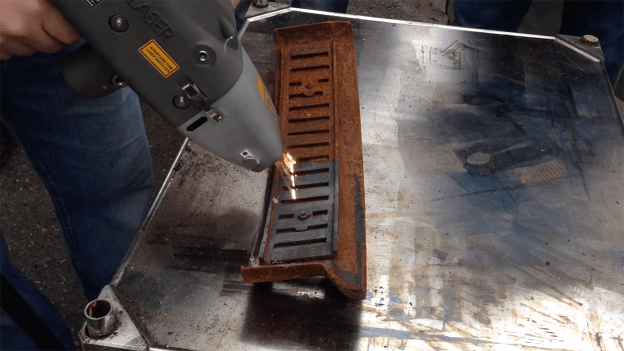

Laser rust removal is a process that involves the use of high-tech products in surface treatments. But note, This process encompasses the use of laser cleaners. These are machines that clean out rust from surfaces without using chemical reagents, mediums, or water. Instead, the cleaners use laser technology, which is very effective- it’s tested and proven. Laser cleaning can be used to remove rust from a variety of surface contaminants, the likes of oil, and oxides that occur on steel and other surfaces. Therefore, laser rust removal is a type of cleaning technology, and in this write-up, we discuss how laser rust removal works.

How does laser rust removal work?

Laser rust removal uses laser ablation technology.

What is laser ablation?

Laser ablation, also known as photoablation is the process through which materials are removed from a solid surface by using a laser beam. The content is usually heated by the energy absorbed by the laser causing it to either evaporate or sublimate. When high laser flux is applied, the contaminant is converted into plasma.

In laser rust removal, the laser has to be adequately bright and focused. The brightness and focus directly influence whether or not the contaminant will be heated to plasma or not. The speed at which the rust is removed depends on the type of material from which it is removed. Note, a material that absorbs the amount of output from the laser at wavelength gets heated faster. When the laser is used to remove other kinds of contaminants, it can be set at low power.

However, a rust removal laser has to be strong enough that it can heat the rust components into plasma within the most moderate amount of time. For the process to work, the laser wave laser beam has to be continuous, and the laser intensity has to be high as well.

Regardless of the amount of output that the laser produces, it does not affect the material beneath the rust. The reason is that steel metals and other metals that are susceptible to rust tend to be incredible reflectors of light. This means that they adequately reflect the laser beam away hence keeping it from burning the material beneath the rust. The success of the process is significantly dependent on the ablation threshold of the material.

What is the ablation threshold?

The term ablation threshold refers to the degree of effectiveness of laser removal or cleaning of metal. In simpler terms, it is the grade to which a coating can absorb laser energy. This is one of the lesser-known elements of metals and other materials in addition to conductivity and the likes. But note, different materials have varying ablation threshold degrees; hence the reason why the process is quicker in some materials than others.

Take Away

Laser rust removal is one of the most common ways of cleaning metal surfaces. It is quite popular because it is fast. It is also highly environmentally friendly because it does not require the use of chemicals or any other removal agents. The process is also gentle than when abrasive techniques are applied.