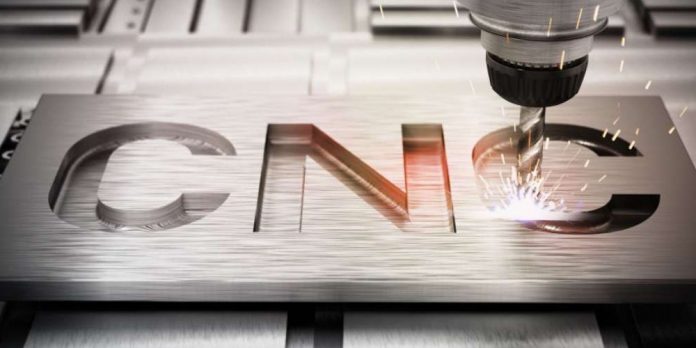

Companies offering CNC services like CNC machining China have been on the rise for quite some time now. As the name suggests, the parts produced are precise, with high accuracy levels. As the name suggests, Computer Numerical Control machining involves the use of computers. The parts made are precise, with high accuracy levels. For such reasons, companies are willing to outsource these services and have products of their own developed. In this post, we expound on the benefits of outsourcing CNC machining operations

Benefits of Outsourcing CNC Machining Operations

Outsourcing involves getting a company to handle your products and everything connected to them and hand them over when done. The importance of doing this is;

1. Development of highly accurate parts

A certain level of expertise and machinery is needed to develop objects with high accuracy and precision. CNC machining is subtractive; thus, excessive material is removed from a workpiece using machines like the milling machine, plasma cutter, lathes, and router. You need to understand the working mechanism of these machines to operate them, but some are too complex. Choosing to outsource the services allows someone with better knowledge of the machine to handle it, and it’s less stressful for you.

2. Make modern processing technologies more popular

The traditional methods of manufacturing were less accurate, slow, and needed too much human effort. Modern manufacturing methods like digital manufacturing came to better the industry. An example is the CNC machining method that produces parts like no other in terms of precision and accuracy levels. This digital process is fast and receives special instructions from codes within the computer; hence it works as desired. The modern technologies used help companies to stay relevant and at the top of their game

3. Saves cost and time

When you decide to produce certain things yourself, you must buy the required machines, get materials, and hire personnel with the needed expertise. You’ve already incurred costs even before the start of production. Also, it takes time to gather every necessary item and may take longer to find the right person to run the machines.

Doing this is commendable if you have the resources; however, outsourcing is good if you have limited capabilities. Handing over the production gives you time to focus on other parts of the business or company. In addition, it saves you the money needed to create an entire processing plant and hire extra people. After a short time, your goods will be ready, and you can use or sell them as you please.

Final Word

CNC machining is one of the best machining processes. Choosing to outsource its services is even better to help keep up with industry trends, modern technologies, and other benefits. Several companies worldwide offer these services, and it’s important to do proper research to get the best. It’s good to choose a company near you to save on costs. However, if you decide to outsource abroad, like China, consider the shipping costs, plan, delivery, and product tracking.