The Chinese would use paper for about three centuries. That is before CE 105, a time when Cai Lun was the Emperor of the Han dynasty. He officially told the people about the invention of a new printing method using paper.

At that point, the Chinese began to print papers. But that has since changed under the dynasty of Tang. It collapsed as new experiments with movable printing types became the norm of printing in the industry. Today, industries use gravure laser printing for their tasks.

The printing method is characterized by impeccable print quality coupled with a high speed. It also comes with several advantages. It involves a unique yet straightforward printing process, the proper use of ink, and the machine’s flexibility in printing. To learn more about the impacts of gravure printing in the industry, click here.

Changes Made by The Printing Technologies

Because of several technological innovations, laser printing using gravure belongs to an influential group of innovative technologies. The packaging materials industry is one of the largest in the consumer sector. It is also one of the largest with the demand for gravure printing.

The Bases of Gravure Printing Processes

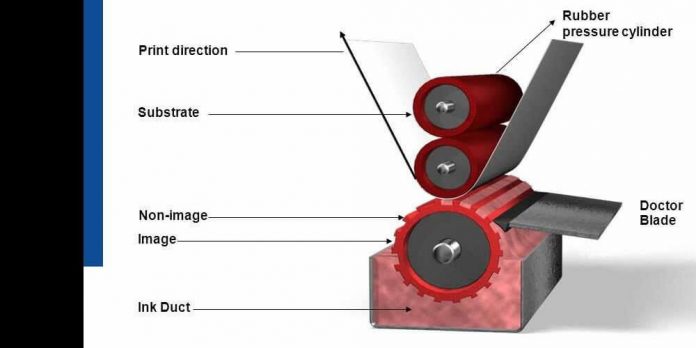

Gravure printing uses an indented plate with a large surface area for printing. A fluid is then put on the plate. The excess is often removed for the printing process to occur. This should leave the areas that are raised ink-free. Eventually, ink is transferred from the areas that are depressed.

For professionals seeking simple but tech-based printing methods, this is yet another form of printing to consider. It is conducted as a web process. Usually, the printing occurs on lightweight coated wood paper.

Minimal pressure is exerted on the surface area. Therefore, the smoothness of the paper is crucial to the success of printing. Some of the components of the rotogravure are such as the plate and the ink. A fountain is used in that case.

Experts can also use a doctor blade to yank out the ink from the nonprint area. That is why most professionals in the printing sector prefer this printing method. So, what changes has it brought to the printing industry?

Gravure printing is simple yet comes with a high yield. The printing has been used on various occasions to prepare several OTFTs. In the past, the likes of Hambsch printed their materials strictly using this method because it is more efficient. Given that it comes with a high yield, it is the most preferred printing method of all time.

The Use of Various Inks for Printing

Professionals in the printing industry still notice considerable developments in this printing method. A common trend in it is using different ink types. This is where the scented ink comes in. Customers can also enjoy the availability of holographic inks and soft touches.

Final Thoughts

Gravure printing is perhaps one of the simplest in the industry. The straightforward application process makes it unique in several ways. That is why it is extensively used in most narrow web industries. To date, more marketing and research sectors are indulging in this printing process.