The CNC plasma rotary cutter industry is evolving with new technologies such as 3D printing introduced into the market. Even with the introduction of such mechanisms of working, CNC machining is still a commonly used way to produce various metal parts. From aeronautical, medical, food to automotive industries, all are customers to CNC machining services. Thus, it would be helpful to understand the top 5 machining techniques in the market.

1. Surface Grinding for Metal Shaping

Making a flat surface on a metallic structure is essential for several applications. One of the best ways to make a precise surface is by using a grinder. This feature spins a disk covered with a grit of coarse abrasives. The workpiece is also usually mounted on a table then moved beneath an abrasive wheel in many cases. You should notice that the wheel moves at this juncture.

2. Cylindrical Grinding

Cylindrical grinding is an extensive combination of copper as the principal heat conductor for electric charge. Thus, when using a new wire, the conductor will get eroded in the process of dicing in a technique that needs a pass-through and may not be used in a blind hole.

The Wire EDM is then used on thick steel to make semi-circular features. These features can be challenging to design with traditional cutting tools.

3. Milling

There are different milling processes on the market. There is the turning one, which is held via a stationary, then there is the cutting one, which comes with a rotating tool located on the spindle.

But on this type, note that the workpiece should be based on a table that quickly moves in two main directions: X and Y.

The spindle plays a significant role in holding tools. It also directs them to the three principal axes, namely X, Y, and Z.

While the mill can drill various holes and bores, it will remove significant stock, which may get complicated from the symmetrical parts.

These mills are then used to design square and flat faces coupled with chambers and notches. The features work together to enable efficient operation as a cutting fluid is also used to help cool the workpiece.

A cutting tool facilitates the whole CNC machining operations.

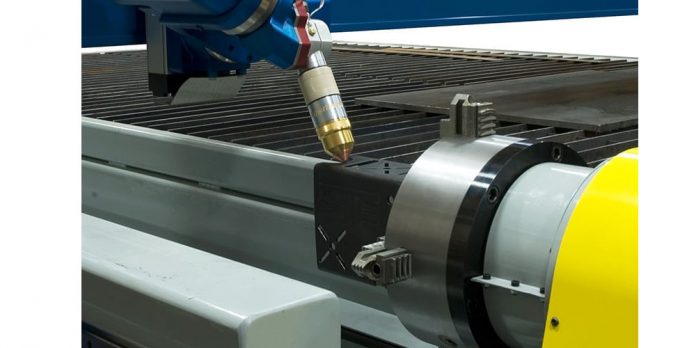

4. Plasma cutting

Plasma cutting uses an impressive machine cutting technology. It entails blowing gas at high speed via a nozzle and generating some electric arc through the nozzle from hot plasma to the desired material. The cutters are also primarily used on metallic structures even though other materials can be used in many cases.

5. Waterjet Cutters

A waterjet cutter is a CNC tool that can slice into metal and other materials such as granite using high-velocity machinery and pressure from the water. The water herein can quickly be loaded using an abrasive element such as sand or filings. The technique herein is often utilized in fabricating various parts for devices and other machinery.

Final Thoughts

There you go. If you work in the CNC machining industry and are interested in understanding various processes involved in cutting and shaping materials, this blog post is meant for you. Happy learning and exploring!