Sandwich panels are roof and wall insulation materials. They can also be referred to as cladding materials since they act as thermal insulators. These panels are highly applied in a wide range of industries because of the numerous benefits they offer. They are made of three materials. The term “sandwich” is used because the insulation material is sandwiched between two thin metal components. These components are mostly made from either aluminum or steel. Wall sandwich panels are popular because of their ease of installation.

The process of installing wall sandwich panels

The first thing you take care of before you start the installation process is choosing suitable material. The best thing to do is choose a reputable brand. After selecting the right sandwich panel, you can follow the following installation guide;

1. Transporting the sandwich panels to the construction site

After purchasing the panels, the next step is transporting them to the construction site. This is an essential part of the process because improper transportation could result in severe damages. The mode of transportation you use depends on the size of the sandwich panels. For instance, if you have 6-meter panels or less, a forklift is the recommended transportation equipment. For anything more significant, a conveyor belt of spreader boom would be ideal.

2. Quality control

Before the installation process begins, the completes structure has to be inspected. Quality control is done to check whether the structure is straight and meets all the construction standards. Note that the slightest deviation in implementation could result in leaking at the joints between the panels. Therefore, quality control is an essential step of the installation process.

3. Removal of the protective film

Once the structure has passed the quality control tests, you can start the installation process. You can start by removing the film before you start installing it.

4. Sealing

Before fixing the panels on the wall, you can start by attaching PES sealing tape. The sealing tape needs to be fixed to the structures where the sandwich panels will contact the construction. Using sealing materials can prevent damage to the lining of the structure.

5. Installation

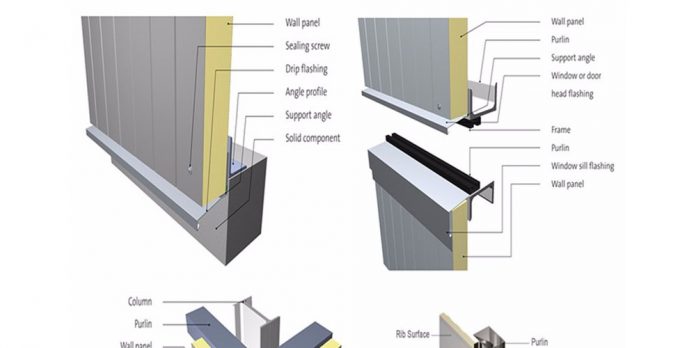

You will need fasteners for the installation process. When installing the panels, you will need to penetrate the entire thickness of the panel to the structure. You must also practice caution to ensure that the sandwich panels do not get broken or damaged during the process. You can use vacuum lifts to transport the panels during the installation.

When it comes to installing the door, window, and skylight profiles, you will need particular types of panels. You may also require professional assistance as the process tends to be more complicated than installing the panels on the wall.

Conclusion

As mentioned in the introduction, installing sandwich panels is not as challenging as most people assume. It means that you do not need to spend a lot of time and money in the process. It also implies that you can make a DIY project out of it without requiring any technical know-how. This is one of their primary advantages.