FDM 3D printers are giving other common brands a run for their money. Their demand is on the rise. But what really does this type of printing mean? How does it work? To get the right answers to these questions, care to read our blog post in detail. Fused Filament Fabrication is also known as an additive manufacturing process in the material extrusion department. When it comes to FDM 3D printing, the object in question is built selectively by depositing melted material into a pre-determined pathway in layers. The materials utilized in this case are most of the time known as thermoplastic polymers. They are pure filaments.

That said, FDM is one of the most common 3D printing technology in the world. It highly represents one of the largest installed bases of various 3D printers internationally. The printing idea is also the first technology type that most people in the printing industry are fully exposed to. In this blog post, we shall highlight key technological areas to look into in the FDM printing world, especially when it comes to fabricating a significant part with the FDM- this should assist users in acquiring excellent results in the long run.

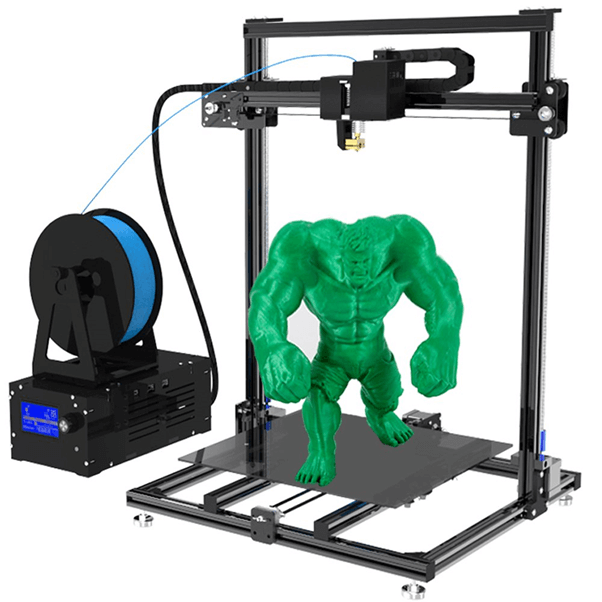

In layman’s language, fused deposition modeling is a prominent method of additive manufacturing in which the materials of layers are fused to form an object. Thereafter, the content is melted past the temperature of the glass transition. It is then extruded in such a way that the previous extrusions can create an object using the initial layers. A standard FDM 3D printer will take a plastic filament and then squeeze it into the hot end, melt and finally deposit the layers on the bed.

There are different types of materials that can be used in these FDM printing methods. They include chocolate, pastes, in addition to wood.

FDM is significantly accepted as one of the simplest ways to achieve quality 3D printing. It is also affordable and, most importantly, efficient.

We have mentioned that FDM successfully builds 3-dimensional parts through melting as well as advancing the fine plastic ribbon via computer-controlled extrusion. Here are detailed steps of how FDM printing occurs.

- Pre-Processing- The pre-processing phase starts in one of the two build-preparation programs. These phases include CatalystEx or, better yet, Insight. During operation, the first step entails importing a design file and then picking options as well as creating slices and layers. The next step involves the pre-processing software calculating various sections and designing them into layers.

- Production- This is the second phase of the FDM printing process. The user should press print to start the entire building process. Thereafter, the two materials are inserted into the head of the extrusion, and then heat is applied. The temperature should then soften the plastic, which is the raw material in this case.

- Post Processing- Post-processing refers to the removal of a disposable product, which is usually the support material. The user can finish up by washing as well as stripping away the available support material traditionally held up in place.

Take-Home

Most FDM systems will allow you to adjust several parameters, such as the temperature of the nozzle as well as the build platform and speed. You will also be in a position to adjust the height of the layer coupled with speed. Your operator often sets these. Therefore, they should not be a significant concern to the designer.