Road milling, an often overlooked but fundamental aspect of asphalt and concrete industries, is a game-changer in the sphere of road maintenance and construction. The linchpin of this entire operation is the road milling teeth, integral components that directly influence the quality, efficiency, and precision of the milling process. Visit site to learn more.

Working Principles of Asphalt and Concrete Road Milling Teeth:

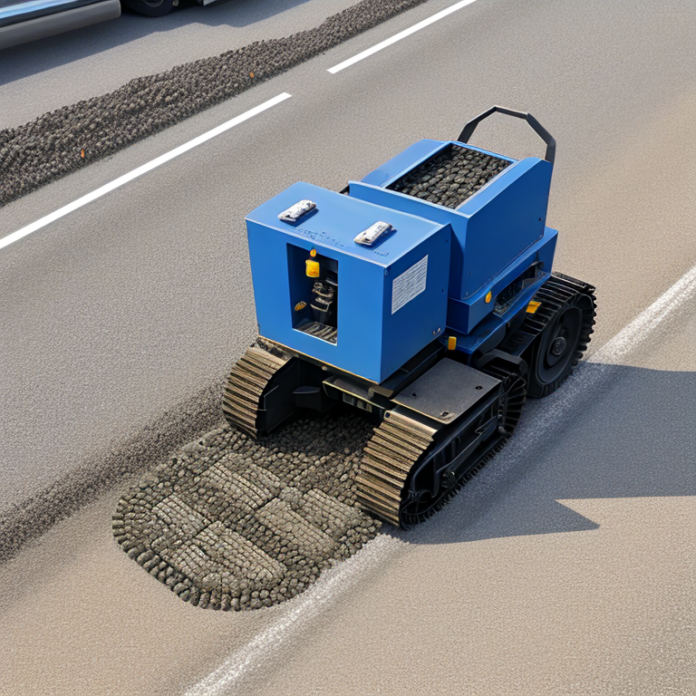

Road milling teeth are the unsung heroes behind the precise cutting of asphalt and concrete surfaces. When these teeth make contact with the surface, they break it down into manageable fragments for easy removal. Their efficacy is largely owed to the rotational movement of the milling drum that hosts these teeth, thereby leading to the constant chipping away of the surface.

The efficiency of the milling operation is intimately tied to the design and configuration of these teeth. Various road conditions warrant specialized teeth designs. For instance, while a tough, abrasive surface may require a more robust, sharp tooth design, a softer surface may fare better with a tooth of a flatter configuration.

Application Insights for Asphalt and Concrete Road Milling Teeth:

Road milling teeth have proven invaluable in a plethora of scenarios involving asphalt and concrete surfaces. These range from road construction and repair to pavement resizing and even erasure of road markings.

However, the process isn’t devoid of challenges. Milling operations for asphalt, which is relatively softer, often call for less aggressive teeth, whereas concrete, with its inherent hardness, necessitates the use of robust and sharper teeth. The judicious selection of the appropriate tooth type tailored for specific applications is thus crucial.

Benefits of Asphalt and Concrete Road Milling Teeth:

The utilization of appropriate road milling teeth can dramatically amplify efficiency and productivity in road construction and upkeep. They enable the swift and precise removal of old pavement layers, resulting in substantial savings of time and resources.

Road milling also augments surface texture and skid resistance, thereby enhancing road safety. Furthermore, in comparison to conventional road building methods, road milling teeth offer superior cost-efficiency and present a greener alternative due to the potential recycling of removed pavement materials.

Maintenance and Care Tips for Road Milling Teeth:

The lifespan and performance of road milling teeth are heavily dependent on their maintenance and care. Proper cleaning and storage after use can ward off unwarranted wear and damage.

Routine inspection and prompt replacement of worn-out or damaged teeth are essential to maintain peak milling performance. Neglected damage can disrupt the milling process, causing inefficiency and escalating costs. By adopting good maintenance practices, the longevity and performance of road milling teeth can be greatly enhanced, resulting in substantial long-term savings.

Conclusion:

To wrap up, a thorough comprehension of the working principles and application nuances of asphalt and concrete road milling teeth is of paramount importance. The correct selection of milling teeth can have a profound impact on the efficiency, cost, and ecological footprint of road construction and maintenance processes. As we continue to develop and maintain our road networks, the critical role of these simple yet significant tools is clear. Implementing conscientious maintenance practices can further extend their longevity and performance, resulting in superior outcomes and notable long-term benefits.