On-demand manufacturing services refer to a process of fulfilling customer’s order for a product they want to be custom-made. Subsequently, this service has significantly transformed the manufacturing industry. Unlike traditional manufacturing methods, additive manufacturing has come with a lot of benefits to both the clients and the producers. Some of the benefits in question will be discussed in this article.

- Broader product range

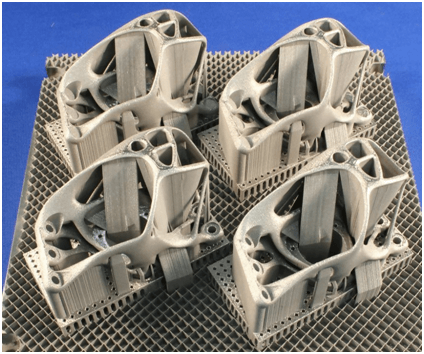

Unquestionably, the additive manufacturing market has dramatically widened. The manufacturing in question enables the manufacturer to make various on-demand items, unlike traditional construction. Consequently, the market share for on-demand manufacturing services increases, thus giving the manufacturer jobs.

- Fast production rate

Indeed, manufacturing speed is essential for a manufacturer to be able to satisfy the market demand. However, on-demand manufacturing solutions have helped in resolving this challenge. While using addictive manufacturing, you only require the necessary raw materials and computer-aided design to make a product. Conversely, in traditional manufacturing methods, longer time to set up is needed, leading to a slow production rate.

- Instant quotation

Due to the technology advancement, application of additive manufacturing has made it easier for manufacturers to make a quotation. Based on design documents and the materials bill review, the system can provide a timely cost quote. As a result, it makes manufacturing to be more productive and quick.

- Eliminates material wastage

Material wastage should be avoided in manufacturing industries as a way of reducing cost. Consequently, with on-demand manufacturing fashion, the wastage in question is well minimized since it only manufactures what the client has ordered, thus avoiding leftovers. Also, with this technology, it helps you measure the design of the product to be made, thus enabling you to produce what your clients like.

- Cost-effective production

Unquestionably, on-demand manufacturing platform allows the suppliers to effectively combine various small raw material orders into a bulky one, thus utilizing the transportation cost. Consequently, this reduces the production cost hence enabling the producer to manufacture their products at a competitive rate. Besides, it allows the producers to sell their products at a relatively low price.

- Better production runs

One of the significant advantages of additive manufacturing is enabling the manufacturer to have better management control. For both bulk and short-run projects, the manufacturer can manage the necessary processes on time, to meet the clients’ needs. As a result, the service enables the manufacturer to have a production control and satisfy the customer’s wants.

In conclusion, Generally, additive manufacturing has significantly contributed to the manufacturing services industry. For example, it has widened the product range, fastened the production rate, enabled instant quotation, and helped in eliminating material wastage. Additionally, it has facilitated a cost-effective production and improved the management of production runs. Consequently, the clients have been happier to get the needed services while it has also assisted the manufacturer in meeting the client’s demands.