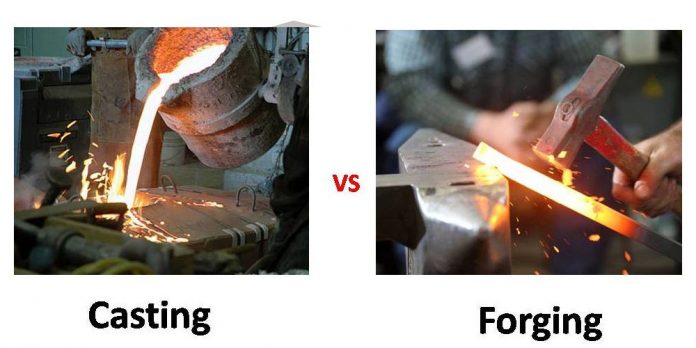

If you have been looking for a way to create your metal into final products, then you must have come across several processes. The top two that most people know about are metal forging and metal casting. If you have no idea how these two are like, then you might be at a crossroads on which one will work for you. Knowing the hot forging parts and the metal casting processes will help you decide what you should choose for your products. Do not be in a rush to pick one over the other unless you have done sufficient research. Here is what you need to know about the two processes and how to use them for your good.

What happens in metal forging?

Metal forging turns the metal into a liquid state before it molds it into the final piece. As such big piece might be hard to form with this process because it means moving around a lot of molten metal. In case of a mishap, it could lead to injuries and a lot of metal going to waste. The other thing with this procedure is that you will end up with a heavier final piece because every bit of the molten liquid is used. Here are the main reason why you should use metal forging

- It produces stronger and more resilient pieces than all the other processes.

- The process reduces the risk of metal porosity, cavities, and shrinkage.

- Since it has a tighter grain, you will get more strength with the metal. You do not need to use expensive alloys to get the same effect,

- It offers better resistance to water which means you will not have to worry about the metal rusting anytime soon.

What happens in metal casting?

Similar to the forging process, metal casting is mostly used when there are bigger parts to make. While forging uses alloys, casting uses ingots since it has been used for a long time. More people trust the process. Here are the main reasons why most people prefer metal casting:

- It can handle more weight. If you need a heavier piece or product made, you can use this method.

- You have a variety of metals to choose from

- The tools used are cheaper when compared to the forging dies.

- It needs fewer production runs for it to start mass production.

- It can work on complex pieces and get the details in as well.

Choosing between metal casting and metal forging

With all the perks above, it can be hard for you to settle on a process. Here are some tips on what you need to look out for when you are choosing a process:

- The size of the product you want to make

- The amount of money you have

- The metal you plan on using

- The company you work with.

All of these will go a long way to determine what you end up with.

Conclusion

Getting the right process for you will ensure that you can get quality products. Take your time and do your research before you settle on one. It will ensure you choose what works for you.