There are different types of face mask markets and mask making machine: the veterinary mask, hospital mask, dental mask, as well as industrial mask. Geographically speaking, the industry has been divided into different states and countries, including China, the US, India, and Europe, among others. Apparently, the US has the largest share market. The international market exceeds 30 percent. China takes the next lead with a market share of 24.7 percent.

That said, the objective of this study is to define and then project the actual size of the mask machine market based on companies, types of masks and machines, and the users. We also take an overview of the technological advancements in the mask making market.

With different tables to help analyze the global market of face masks, our research offers tangible statistics on the actual state of the market and valuable source of tremendous guidance for people interested in understanding the shifts in curves.

The report additionally focuses on the globally leading market players of the face mask business while providing critical information, including product pictures, specifications, price, revenue, and cost.

The upstream raw materials coupled with equipment analysis are also conducted in this research, which states that the global market trends have recently taken a different but positive shift. Finally, the actual feasibility of the new investment projects is usually assessed when the overall research conclusion is provided.

New Technical Advancements In Designing Face Masks

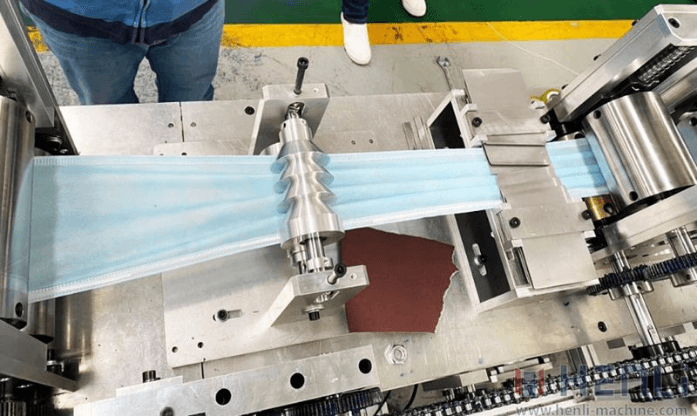

Of course, there are revolutionary technological advancements in the surgical mask making industry. This new technology is innovative enough to improve the efficiency of the face masks machines when it comes to speed as well as accuracy.

Also, the technology is set to enhance the safety of the machine while keeping the user safe. It also plays a role in eliminating the different possibilities of malfunctions that are going to harm the machine’s health when it is time to handle production.

Besides, new technology can improve the efficiency of surgical masks.

Challenges Experienced During The Production Process

During the process of production, you can come across some drawbacks with the machine’s operations. We have highlighted some of the issues you may encounter. We have also shared insight on how to provide solutions.

1. Poor Cutting Of Face Masks

Another challenge you may experience is noticing that the final products have varying sizes because of the poor machine calibration. This can also be appended to the poor machine alignment, which can result in poor uniformity of different cuts. To sort this, you need to calibrate the machine parts appropriately.

2. The Material’s Inability To Flow

You may find out that the materials aren’t flowing from the hopper of the product because of slow speed. This may be a result of a particular blockage found in the system or, worse yet, poor calibration.

But this can be sorted out by appropriately calibrating the machine as well as removing the actual remaining pieces that have clogged the system. At the same time, you will be in a position to increase the programming speed of the face mask making machine.

Final Thoughts

There are times when you will deem it essential to increase the efficiency of the mask making machine. You can begin by calibrating the machine to get the right edges and points. You can also train the people you work with on some of the best production practices on the market.