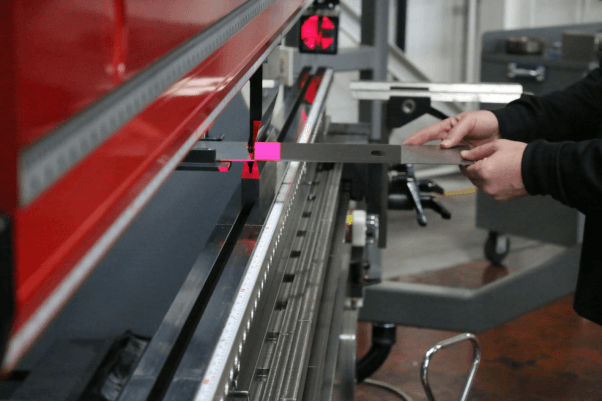

As initially discussed in our earlier blog posts, a press brake is a device used to bend a metal sheet into a shape determined by a set of die (Have a look at press brake here). It will later form different bends by holding the workpiece in between its punch and the collection of the die. Now that you understand the mechanism of the device, it is essential to understand some of the applications of press brakes in different industries. Read this article to learn more about the types as well.

- Metal Bending

Press brakes come in a variety of types. One such model is the hydraulic press brake, manufactured by trained professionals. By the time it reached the market, it is usually known as a bending machine ready to use. In this case, it will be used for bending storage tanks and chimneys. The device has a strong clamping feature coupled with a bending capacity. It also has a modular design to facilitate a changeover. Other than that, a hydraulic press brake comes in a variety.

2. Sheet Cutting

Metal cutting is a complex process. It not only requires the knowledge and procedure but strength too. This implies that it is not possible to cut a sheet using bare hands. A press brake comes in handy in such cases. At the same time, one technology that is employed in trimming a metal sheet is sheering. The name of the process hails from the operating mechanism, which involves exerting a lot of pressure on the metallic device. The press brake will cut metal sheets of different sizes.

3. Metal Shearing

Metal sheering using press brakes is a significant fabrication process. Usually, it is applied in cutting straight lines on a flat sheet of metal. During the process of shearing, two blades are utilized. That is the upper and lower blades. The blades will be forced to pass against each other, leaving a space in between. At one point, these blades will remain stagnant. The process of metal shearing entails a press brake’s ability to make a straight line on the metal.

4. Cutting Metals Into Particular Angles

Metal cutting has been discussed at length. You can always use your press brake to achieve that. Of course, there are other machines apart from press brakes, which you may use as well. But, in cases where you need to achieve a specific angle, you may have to use a unique press brake. It must have been designed for such use. That way, you can get that specific angle. Besides, cutting metals to certain angles can be complicated. This is because of the need for accuracy. It is for such a reason that you may want to use a press brake. You shall be successful in that project.

Take-Home

A press brake is a sturdy device. It is also durable. That is why it can be used in metal cutting and shearing. To purchase a reliable machine, contact a company with vast experience in retail.