Industry

Pencils Bulk: The Smart Choice for Businesses and Schools

Getting pencils in bulk is a great business opportunity [ ]

Industry

How to Label Your Kitchen for Enhanced Organization and Convenience

Is your kitchen a chaotic mess with ingredients and ute [ ]

Industry

What Does ASTM A135 Grade B Pipe Specification Say?

For Electric Resistance Welded (ERW) steel pipes that t [ ]

Industry

Features and Benefits of Ram BOP Bore Size: 13 5/8″

Oil drilling is a laborious and advanced process to sli [ ]

Industry

ASTM A252 Piling Pipe: Material, Structure, and Performance Analysis

As the demand for stronger and more reliable structures [ ]

Industry

Driving Sustainable Manufacturing: The Environmental Advantages of CNC Machining

In today s world, the call for sustainable manufa [ ]

Industry

Delving into the Heart of Road Construction: An In-depth Study on Asphalt and Concrete Road Milling Teeth

Road milling, an often overlooked but fundamental aspec [ ]

Industry

Forge Car Parts: The Ideal Choice for Enhancing Vehicle Performance

When it comes to optimizing the performance of your veh [ ]

Industry

The ultimate guide to automotive prototyping

Developing high-quality auto parts and components that [ ]

Industry

Choosing between a 2-post and 4-post lift

Choosing between a 2-post and a four-post lift can be d [ ]

Industry

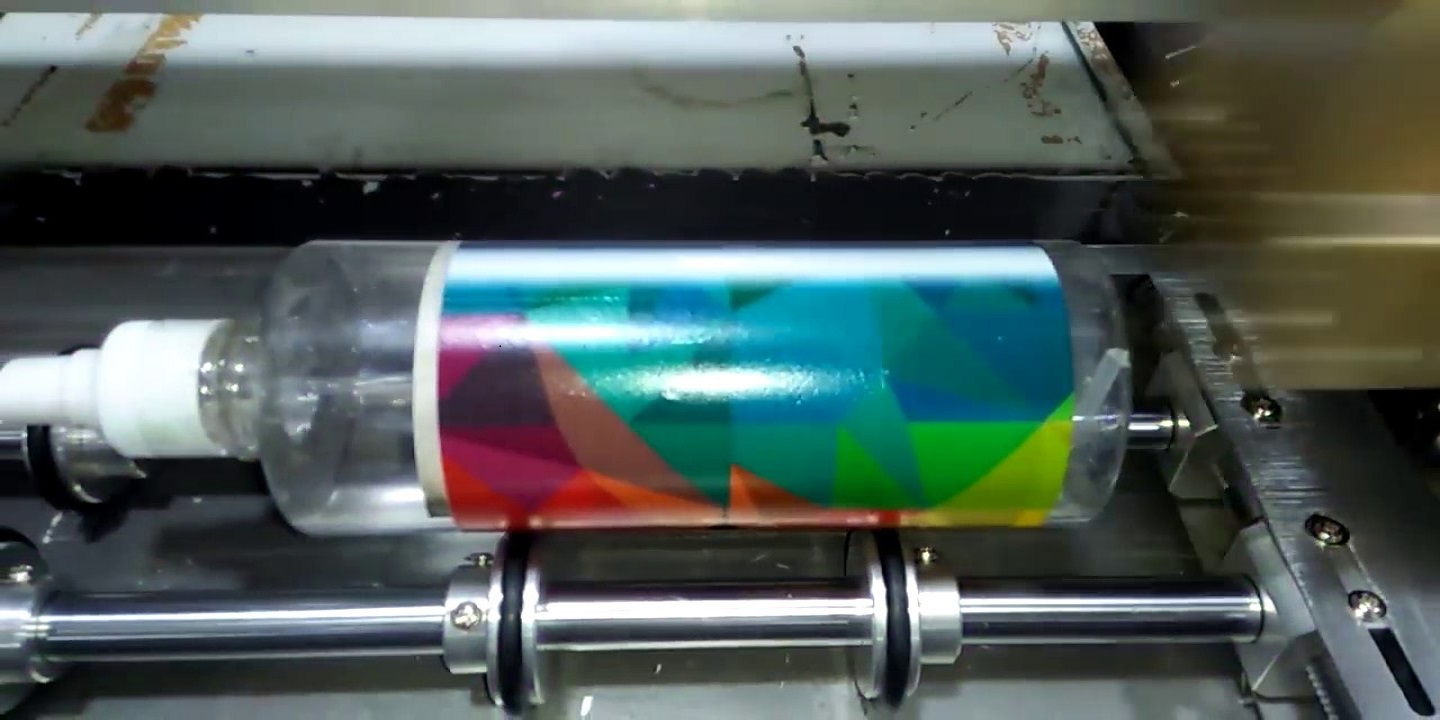

Bottle Printing – Unlocking the Possibilities of Personalization with Bottle printing machine Technology!

When it comes to personalized items, bottle printing is [ ]

Industry

Importance of Using Automatic Shoe Cover Dispensers in Health Facilities.

Worker safety is a fundamental aspect of employment and [ ]